Learning from Lotus

22/09/2011

A coconut peeler invented by RMUTT students

22/09/2011Generally, bringing waste oil from the house usage to produce biodiesel is the most significant valuable toward environmental conservation because it can add value into useless thing and create massive benefits as an alternative fuel.

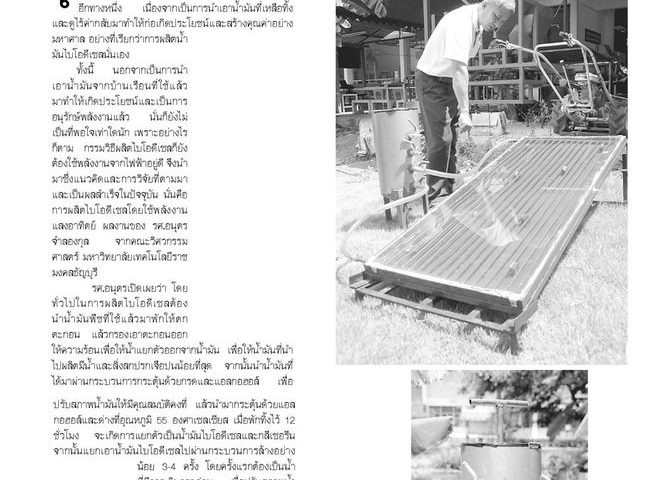

However, using waste oil from household consumption has not been extremely satisfied because the process is still dependent on electric power. This led to an innovation idea to utilize the natural energy power; this is a solar energy. This project launched by Assoc. Prof. Anut Jamlongkun, a teacher from the Faculty of Engineering, Rajamangala University of Technology Thanyaburi (RMUTT),

Assoc. Prof. Anut said that “normally, biodiesel production is initiated from water and waste removal by filtering the waste out and using heat to separate water from the oil. Then, process it into oil condition adjustment stage by stimulating its quality with adding acid and alcohol. After that, separate biodiesel and glycerine by putting alcohol and base with 55 degrees Celsius of temperature about 12 hours. Then, purify biodiesel repeatedly about 3-4 times with the heat in order to get the pure biodiesel. Please note that the first time there must be to put weak acid to balance the conditions of biodiesel at pH=7.”

From above the process, there would be seen that the heater is the most important part to produce heat. Formerly, it used electricity but new innovative method uses the solar radiation. It will generate power by using flat radiation receivers. The power is controlled at 60 degrees Celsius to gain the most appropriate quality.

Successfully, the biodiesel quality is equal to the normal method producing. However, this new innovative process involves vividly in an extremely environmental conservation in the whole production chains, starting from upstream by bringing used oil into biodiesel production through heat production by sun radiation.

Translated by Mr. Suraporn Onputtha