RMUTT develops ‘Egg White Donut for chronic kidney disease patients

18/07/2019

RMUTT showcases its research work on an innovative invention of ‘Soil and Underground water contamination’ detector to help preserve our environment

26/07/2019RMUTT researchers produced a textile product “Loincloth” from rice straw

‘Loincloth dyed with natural colors made of rice straw” is a textile product manufactured by Ban Nong Kovit village in Khao Chakun district, Srakaew province. This amazing apparel was originally designed by Ajarn Koranut Suksawat, a researcher and lecturer in the department of Fashion Design and Apparel, Faculty of Home Economics, Rajamangala Univesity of Technology (RMUTT). The apparel design of the loincloth is aimed to be as a part of garment processing and to increase textile product values in 2019 budget. Besides, this design work receives its support in finance and promotion of the OTOP product value from Science, Research and Innovation in 2019 budget.

Aj. Koranut Suksawat revealed that Thai traditional hand woven loincloth of Ban Nong Kovit village has its own uniqueness when compared with elsewhere loincloth. With its eye-catching pattern and special woven technique using Thai ancient loom, its fabrication tends to be strong and ready to be made as work suits or many other special occasion clothing. And thus, this beautiful loincloth of Ban Nongwit village is being accepted as one of the famous OTOP products in Khao Chakun district, Sa Kaew province. In order to further develop its application and meet the commercial standard, Non Kovit loincloth is dyed with natural colors so as to tolerate against washing as well as to develop better clothing pattern. To improve the product value, the fabrics is made to be modern in patterns and designs and must be well accepted by customers and meet the OTOP Science and Technology standard. Moreover, in a way, the product could be sold in international market. As for educating local community, Aj. Koranut Suksawat also educate the how-to of “Loincloth dyed with natural colors made of rice straw” making to the Community Enterprise Nong Kovit.

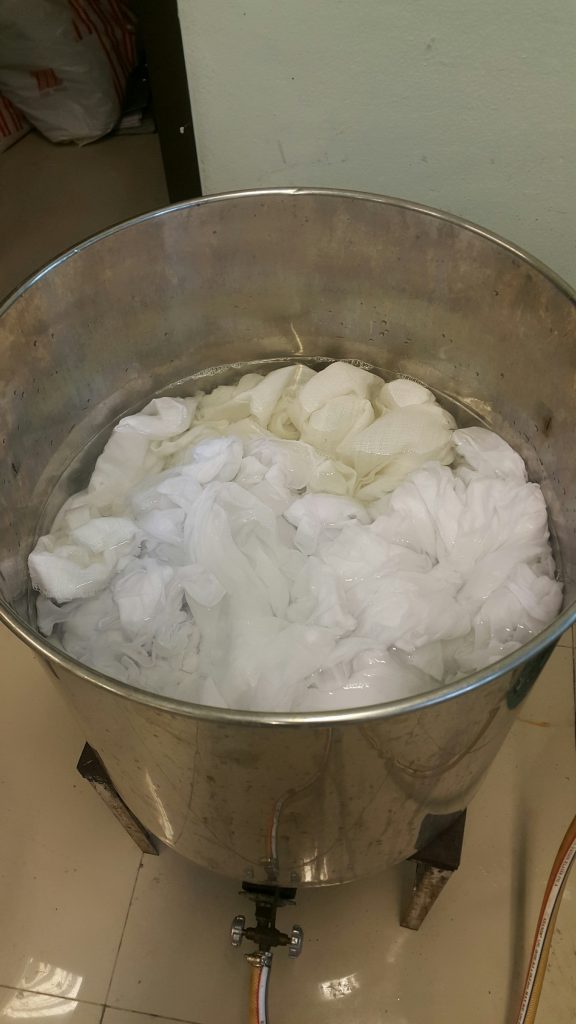

In order to start the dying process of loincloth, rice straw produced by Nong Kovit OTOP group is dyed with Peltophorum pterocarpum bark. For the procedures of dyeing rice straw, rice straw will be boiled in water for 2 hours and then, the cotton thread is soaked in normal temperature water for half an hour before cleaning off its fabric powder. Later on, water will be boiled with eucalyptus leaves for 1 hour before filtering eucalyptus leaves (as dyeing agent) out. Also, cotton fiber will be soaked in eucalyptus water for 1 hour before chopping 1 kilo of Peltophorum pterocarpum bark in small pieces. The ratio of cotton fiber and Peltophorum pterocarpum bark is one kg to one kg. Again, the bark is then boiled in water and left for 1 hour. Apply dyed cotton fiber with eucalyptus leave water in Peltophorum pterocarpum bark water. Use prepared dyed cotton to soak in limewater for half an hour until (limewater turns darker). Twist cotton threads damply and leave them in black plastic bag for 3-5 hours until the color sets. Then dry them in the sun and finally wash the thread with clean water.

After the cotton thread is finished with dyeing process, weaving thread into cloth is processed. Concerning patterns, two types of designs are applied including strip pattern and scotch pattern. These patterns are designed into 1 cm small square grids on the loincloth. The prepared loin can then be turned into textile products including women handbags, bag packs, or fanny bags. Women dresses and men’s shirts, moreover, is now popular and trendy. The uniqueness of cloth is how it looks giving its eye-catching characteristic to its natural color with red tone and light in weight and comfortable. Those who are interested in the Loincloth dyed with natural colors made of rice straw can asked for further details from Aj. Koranut Suksawat at 0-2549-3161-2, 085-6754415.