RMUTT researchers produced a textile product “Loincloth” from rice straw

09/01/2020

‘RMUTT’s Aviation Service Industry Department opens its very first Ground Services Training Facilities

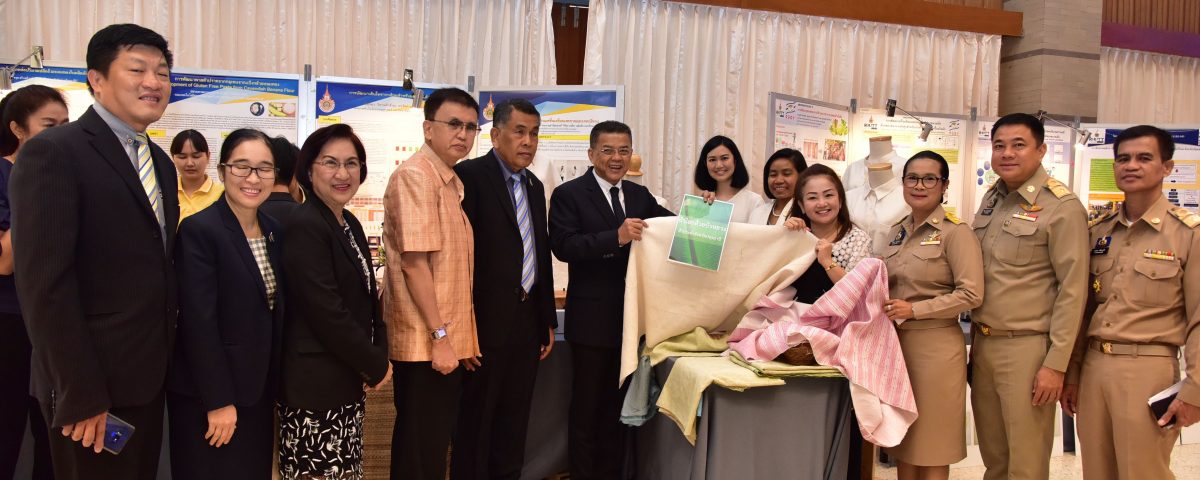

06/02/2020Pathum Thani Provincial Governor joins hands with RMUTT in support of making ‘Bua Luang’ banana fiber as Pathum Thani’s provincial fabric

As for monitoring the progress every 12 months, Rajamangala University of Technology Thanyaburi (RMUTT) and representatives of Pathum Thani Province held a meeting on ‘Thailand’s Challenging and Innovative Project in Spatial Development 2018’ which was aimed to create innovation for solving waste management problems for the communities in Pathum Thani Province. By giving a helping hand to develop Bua Luang banana fiber made by Saeng Tawan Housewife Group, the fiber would then be developed into Pathum Thani’s provincial fabric. Dr. Pinit Boonlert, Governor of Pathum Thani Province, revealed that Pathum Thani Province wanted to create new research innovations especially in the field of banana fiber. Assistant Professor Dr. Sakhon Chonsakhon, Dean of the Faculty of Home Economics Technology who was an expert researcher on banana fiber had been able to turned banana leftovers into banana fiber. Moreover, she also found interesting facts about special properties of ‘Bua Luang’ banana fiber that it was really light in weight and definitely wearable.

With the assistance of Dr. Sakhon, Pathum Thani province had decided to use fabric from Bua Luang banana fiber and sewn them into clothes worn by the Pathum Thani officials. Right now, Pathum Thani Province had put its full support on “Ban Tawan” banana fiber” to be produced by Saeng Tawan Housewife Group. Pathum Thani Province had made the budget for the purchase of machinery such as banana fiber separators and weaving machines In order to keep up with the purchase order and generate revenue for the Saeng Tawan House Group.

Dr. Sakhon Chonsakhon, Dean of the Faculty of Home Economics Technology and Head of Banana Fiber Research and Development team added that it could be found that the banana yarn resulted from spinning process had outstanding properties in terms of their strength and luster making them great for apparel and household products. Additionally, on one hand, producing fiber of banana leftovers would help reduce waste materials from the banana production process and one the other hand, having developed yarn from local agricultural products would help textile industry reduce demands for export of natural fibers making banana yarn yet another interesting choice for eco-friendly textile manufacturing. All in all, this research work could benefit agricultural famers in terms of their incomes and could definitely make banana fiber become Pathum Thani’s provincial fabric.

Ms. Boonnapa Bua Luang, chairman of Saeng Tawan Housekeeper Group, said that the province had attempted to make Bua Luang banana fabric become provincial fabric. The province had been providing support in the production of banana fiber fabric by buying 5 loom machines, a banana fiber separator and a weaving machine for the group. At the moment, the group was able to implement knowledge given by RMUTT representatives to further develop banana fiber fabric with 7 patterns and ready to be manufactured in order to meet needs of the awaiting customers. For those interested in Lotus Bua Luang fiber clothing may visit at Saeng Tawan Housewife Group at Kai Yai Temple Occupation Promotion Center, Sam Khok District, Pathum Thani Province. Weaving demonstrations are given every day at the center. For more information, please contact Call 094-4386587