” Jam Silp” Thesis Exhibition, Department of Design Arts and Technology, RMUTT

28/03/2024

Innovation “Oil Absorbing Foam Technology” for Water Treatment and Oil Capture, Guaranteed with a Gold Medal from NRCT.

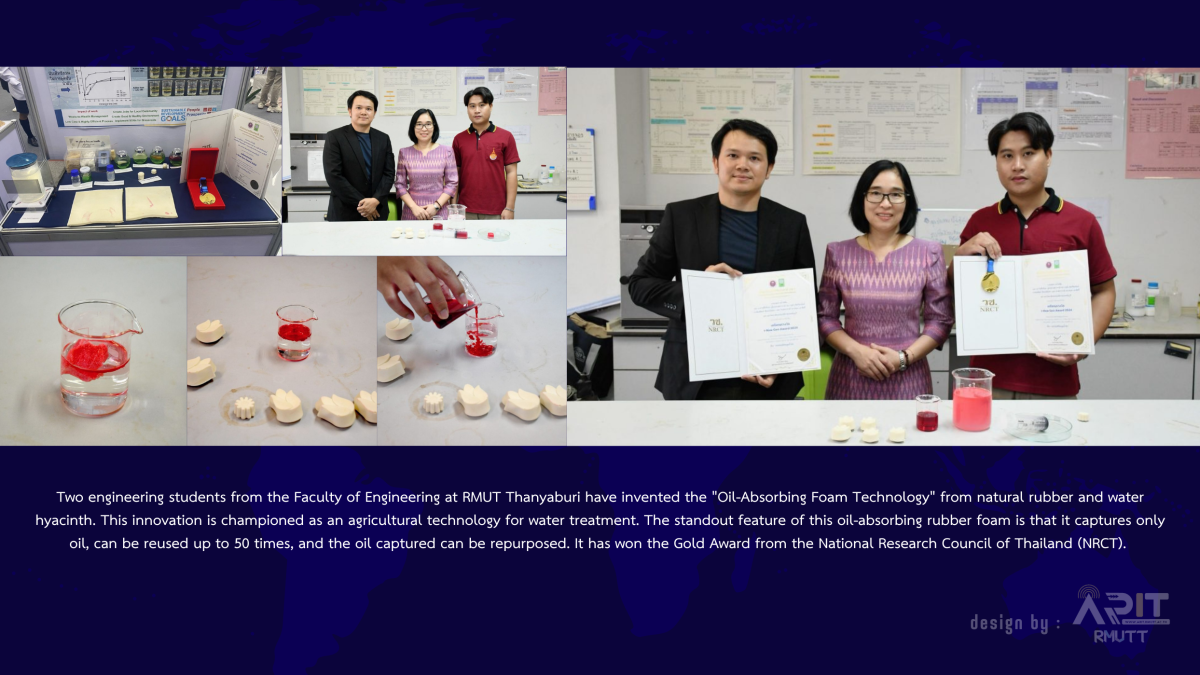

29/03/2024Two engineering students from the Faculty of Engineering at RMUT Thanyaburi have invented the “Oil-Absorbing Foam Technology” from natural rubber and water hyacinth. This innovation is championed as an agricultural technology for water treatment. The standout feature of this oil-absorbing rubber foam is that it captures only oil, can be reused up to 50 times, and the oil captured can be repurposed. It has won the Gold Award from the National Research Council of Thailand (NRCT).

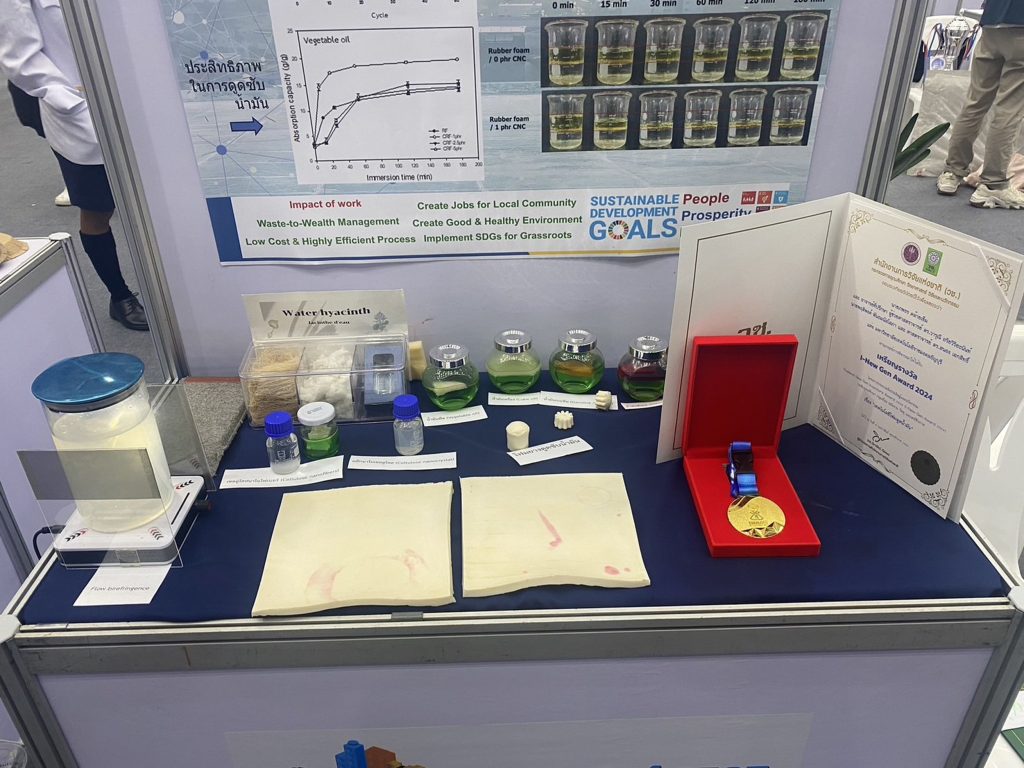

Mr. Popthorn Klaykhem, a Master’s student in the Department of Materials Engineering and Metallurgy, and Mr. Pruetiphong Patamanusopha, a Doctoral student from the Faculty of Engineering at Rajamangala University of Technology Thanyaburi, developed the Green Oil-Absorbing Technology. They were guided by Associate Professor Warunee Ariyawiriyanan from RMUT Thanyaburi and Professor Dr. Sanong Ekgasit from Chulalongkorn University. They recently received the Gold Award in the fields of energy, materials, and biochemistry from the Thailand New Gen Innovators Award 2024 (I-New Gen Awards 2024) by the National Research Council of Thailand (NRCT) under the Ministry of Higher Education, Science, Research and Innovation. This was part of the Inventors’ Day 2567 held at the Bangkok International Trade & Exhibition Centre (BITEC).

Mr. Popthorn explained that the “Oil-Absorbing Foam Technology” innovation originated from awareness of environmental issues, particularly the problem of oil spills in the sea and on beaches, which have immediate and long-term impacts on humans, marine and terrestrial animals, and ecosystems. Developing technology for oil absorption is crucial and intriguing. They collaboratively sought local materials to address this issue and connected with senior students in the Faculty of Engineering interested in materials and biochemistry. They researched the extraction of nano-cellulose crystals from water hyacinth, consulting and collaborating to experiment and produce oil-absorbing foam from water hyacinth and natural rubber.

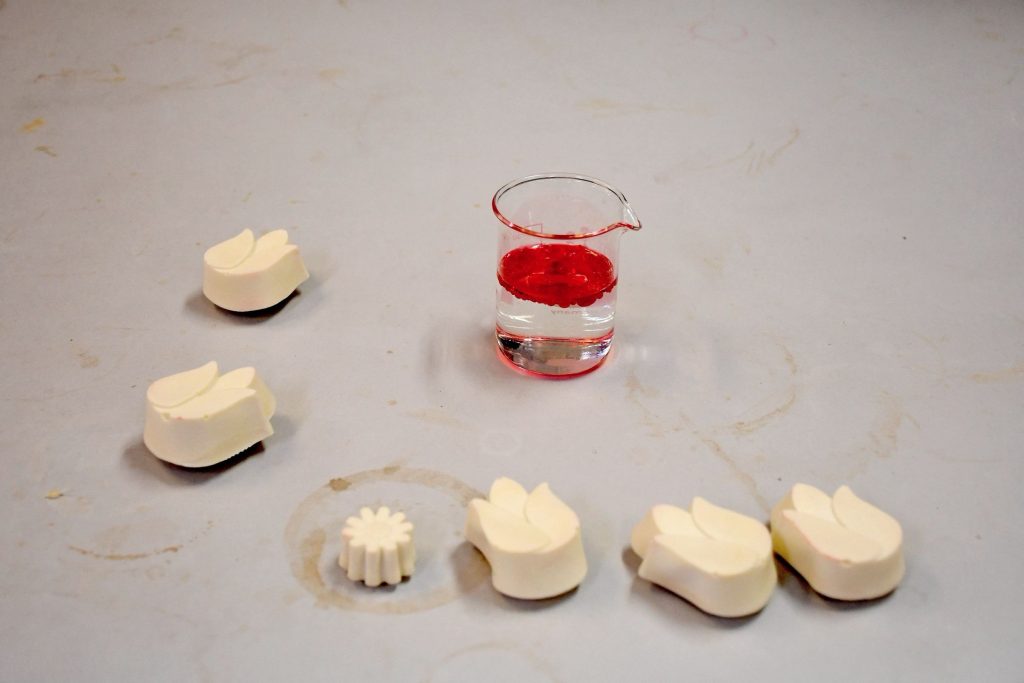

Mr. Pruetiphong explained the production process of the oil-absorbing technology: starting with drying water hyacinth in the sun or with heat, then grinding it into small fibers and whitening it through a bleaching process, followed by fine grinding to extract nano-cellulose crystals. These are mixed with pure natural rubber to shape the rubber foam. The performance in oil absorption and reuse was studied, tested with various types of oil.

“The highlight of this project is that when water and oil are mixed together, the foam acts to capture only the oil. Once the oil is squeezed out, the foam can be reused more than 40-50 times. In addition, the captured oil can be further utilized. Meanwhile, the developed rubber foam is lightweight, low-cost, and easy to transport, making it convenient for use. It can also be shaped into various forms to easily and effectively reach different areas. This project also addresses problems in 2-3 dimensions: reducing the weed problem caused by water hyacinths and promoting the widespread use of rubber when it enters commercial production,” the project owner explained.

Associate Professor Warunee Ariyawiriyanan, a graduate advisor in the Materials Engineering program, added that the curriculum of the Faculty of Engineering emphasizes research that not only achieves international database publication standards but also encourages students to focus on innovation alongside having role models from seniors in the lab. It also supports participation in national and international competitions, focusing on works that can be practically applied, leading to the creation of this project.

This oil-absorbing foam technology addresses various issues, particularly in energy, materials, and biochemical aspects, and is preparing for scale-up and real-world testing, along with further property enhancements. It is an innovation aimed at improving water quality to make it ready for use. For more information, please call 02 549 3400.

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมันนวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน

- นวัตกรรม เทคโนโลยีโฟมดูดน้ำมัน