‘Sommai’ keeps pushing forward its ‘Innovative University’ policy

19/10/2022

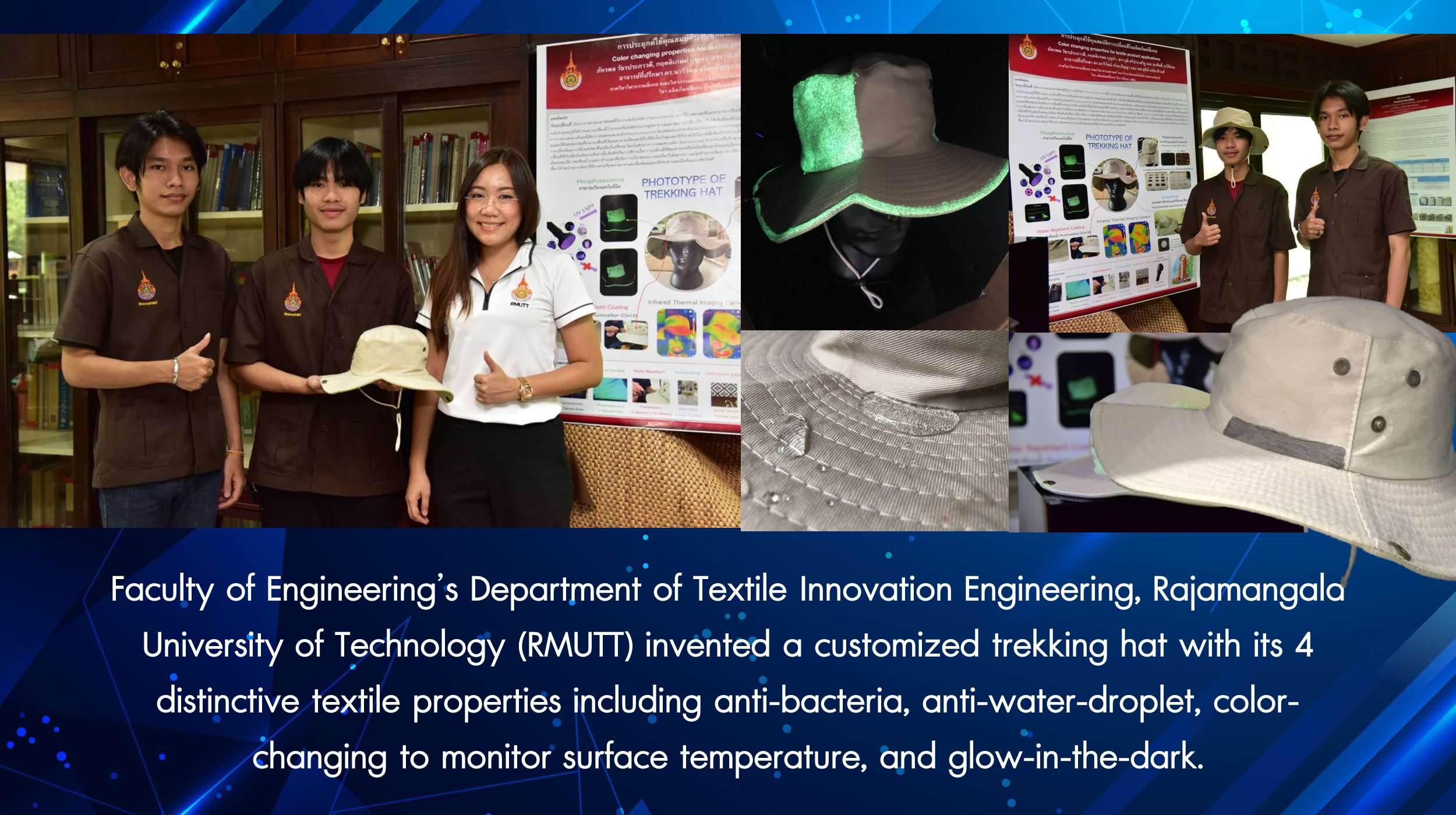

RMUTT invents ‘Anti-bacteria, Anti-Water-Droplet, Color-Changing, and Glow-in-the-dark’ Trekking Hat

02/11/2022RMUTT Researcher magics Special Pure Yeast for Toddy Palm Cake to Promote Local Entrepreneurship

Assistant Professor Dr. Charoen Charoenchai, researcher-lecturer of Home Economics Technology Department, Rajamangala University of Technology Thanyaburi (RMUTT) conducted his research on “Application of Yeast Starter Technology for Toddy Cake (Ka-nom Tal) Manufacturers” to help local entrepreneurs of Sam-Kok district, Pathum Thani, equipped with the necessary life skills to be able to support their wellbeing. This research was funded by Program Management Unit for Area-based Development (PMU-A) – an independent funding unit established under the auspices of NXPO, the National Research Council of Thailand (NRCT) and Thailand Science Research and Innovation (TSRI) under the concept of, “Strengthening economic opportunities and empowering local community enterprise in order to create a prototype community of innovation in a collaborative environment. Dr. Charoen Charoenchai described how local entrepreneurs typically operates within the community, “There are more than 10 fresh Palmyra palm vendors in the area. The products were seen sold in their own stores or in the Ing-Narm Sarm Kok market which is a popular tourist attraction in Pathum Thani. Regarding the process of making toddy palm cake, Toddy palm cake is a one of the more popular Thai desserts made by mixing rice flour with toddy palm flesh, sugar and coconut milk. The ingredients are fermented and steamed. Varieties type of native flora yeast in toddy palm flesh can produce CO2 which will cause fermentation and make the palm cake leaven, soft and spongy. However, insufficient yeast in toddy palm flesh is a problem often encountered in toddy palm cake production. In each batch production, the conventional process of toddy palm cake production cannot produce a homogeneous product and quality control including pathogen contamination and food intoxication becomes difficulty. The research team, thus, applied pure yeast starters extracted from fresh palmyra including Candida suratensis, Pichia kudriavzevii, Zygosaccharomyces bailii, and Kloeckera apiculate during fermentation process of toddy palm cake to help produce a homogeneous product. Dr. Charoen added, not only we transferred the knowledge to Khun Pisamai Uthit and Khun Muenfan Suwannakot who are the owners of the local toddy palm cake shop located in Ing-Narm Sarm Kok market of Sam-Kok district, Pathum Thani, we also offer our technology to Provincial Community Development Office of Pathum Thani in order to fulfil our needs of helping the local people develop quality product, boosting the entrepreneurship confidence as well as promoting and sustaining their local wisdom. Right now we are conducting a research on application of these pure yeasts extracted from fresh palmyra into the ferment process of Cocoa. Since there are a lot of farmers who are trying to produce Cocoa for chocolate making, only some manage to produce them successful due to its low cocoa quality and therefore, we as researchers attempt to help them make good quality chocolate. Ms. Ariya Uthit, a member of Baan Bang Na local community enterprise added, “Back in the past, our process of making toddy palm cake would start by squashing fresh palmyras and hang them for 2 days before we thresh them with prepared flour and coconut milk. However, in order for the mixture to leaven, soft and spongy, we need good sunlight without it, we would not be able to make a homogenous toddy palm cake making much harder for to sell them. Fortunately, with the technology that was transferred by Dr. Charoen we are able to produce good quality cake enabling to earn us better income. If you are interested in the pure yeast that we made, you can contact us at 061-3245497 or call Dr. Charoen Charoenchai at 081-6494337.