How will the education change after the COVID-19 crisis?

23/04/2020

The power of “HCS” learning sources

28/04/2020In response to the demand of global environmental protection, “RMUTT” builds Bamboo straw cleaning machine

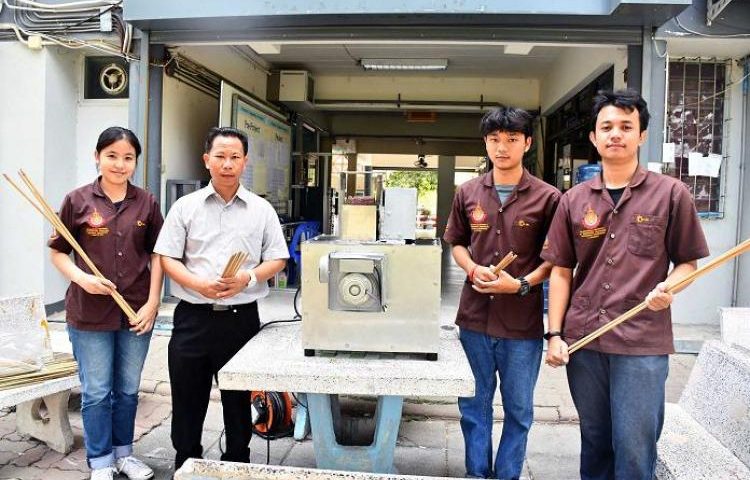

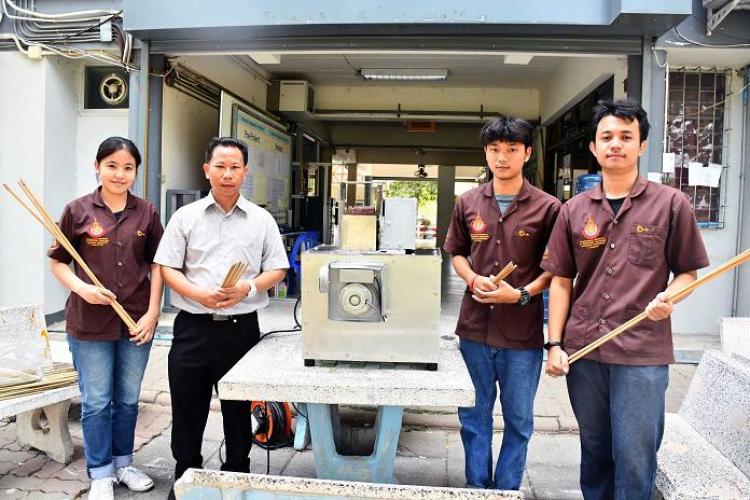

With the current global trend of recycling waste to help reduce the use of natural resources and global warming, a group of researchers and its students of Rajamangala University of Technology Thanyaburi (RMUTT) including Dr. Manop Yamfang, a researcher and lecturer of the Department of Mechanical Engineering, Mr, Sarawuth Laohana, Mr. Sittikorn Sa-nguantrakul and Benjaporn Yuthisart, students of the Department of Mechanical Engineering had been conducting a research on designing and building Bamboo straw cleaning machine with the aim of reducing manual labor that could clean Bamboo straws’ surface 88 straws per hour.

Dr. Manop revealed that with high demand of purchasing natural bamboo straw and vast plantation areas of Bamboo in Prachin Buri, the researchers decided to visit Pimtha Company Limited, a place where bamboo straws and other OTOP products had been manufactured and distributed.

In order to meet the company’s demand of research and development product improvement and product safety standard, RMUTT researchers were asked to help design and build Bamboo straw cleaning machine and to provide sanitizing solution to the straws without piling too much work on their employees that might affect their working efficiencies. Regarding to the funding of the research project, the research team had been given an annual financial support (2019) from Thailand Science Research and Innovation (TSRI).

“The results clearly showed that the machine could clean 88 bamboo straws per hour while human could only clean them 47 straws per hour when comparing bamboo straw cleaning machine capability and human capability. Machine was able to outperform the human of more than 1.87 times; thus, should agriculture workers decided to replace human with the straw cleaning machine, their return rate of investment would be within 0.98 year with the reduction of production cost on an average of 50,964.1 baht per year.

Miss Benjaporn, a RMUTT student from the department of mechanical engineering also added, “the principle of drinking straws cleaning system starts from a single-phase 1/3 hp motor which is an electrically-powered rotary machine that can send electric energy to pulley where scotch bright is attached. While the machine is cleaning the surface of Bamboo straw, the pulley will rotate from left to right and right to left.

When stain on straw is removed with polishing wheel with optimum rotation speed of 400 rounds per minute, dusty leftovers of stain will be sucked out with the installed exhaust fan. In case of higher speed, polishing wheel might be damaging bamboo straw surface while the control capability of machine controller will also be reduced leaving the straw unclean. On the other hand, if rotation speed is lower than 400 rpm, cleaning efficiency will also be decreased.